Are you interested in a career within manufacturing? Here are some tips to help you get started in this field. Knowing the required skills and range of salaries for each type manufacturing job will help you find the one that best suits all your needs. To get started, contact a recruiting agency like Bonney Staffing to find the right manufacturing job for you. You have many benefits working in the manufacturing field.

Manufacturing jobs: Career opportunities

Manufacturing offers many career opportunities for the right person. There is a great demand for skilled workers and a wide range of career progression options. It is gone a time when you had to work in dirty clothes on a production line. The advent of new technology has opened doors to many new manufacturing careers. Manufacturing has many exciting possibilities, including product development, office roles, and marketing. Here are some examples.

Many manufacturing jobs involve physical tasks such as lifting, moving, and operating machinery. Before applying for a job, make sure you consider the physical requirements of each job. Also, make sure you choose a career that allows you to work in an environment with the right hours and flexibly. A list of criteria that you want in a manufacturing job is created. It will be based on your skills and previous experience that you can determine if this job is right.

Skills needed for manufacturing jobs

Different industries require different skills for manufacturing jobs. Although traditional skills such as welding or machining are still required, many industries have moved to computer-automated systems. As they are able to quickly analyze work environments and identify potential areas for improvement, those with analytical and problem-solving skills will be in high demand. Computer application experience is required to operate CNC machine tools and computerized measuring machines. It is important to be able to operate complex machinery.

In addition to the basic skills listed above, manufacturing jobs also require people with good communication skills. With automation taking over many manufacturing jobs the focus has moved to technical troubleshooting programming and preventative Maintenance. Today, factories are seeking skilled technicians who can troubleshoot and maintain assembly lines. Engineers, CNC machinists and lathers are other skilled workers in high demand. High demand for skilled workers in the manufacturing sector will be those who are talented in technology.

Manufacturing jobs offer a wide range of salary options

Manufacturing jobs have a range of salaries. While the highest-paid workers may earn $37.500, others can make only $17,000. The average salary for a Manufacturing position is $24,000, but you can expect to earn more than that if you are experienced and able to handle higher-skilled work. Your salary can increase depending on where you live and how many years of experience you have. To find out more about the average salary, check out our salary guide for manufacturing jobs.

Manufacturing jobs have a wide range of salaries, depending on industry. California, Santa Clara and Fremont employees make an average of $28,835 per year. In fact, these three cities have the highest Manufacturing salary in the nation. If you are in the manufacturing industry, you can expect to make between $50,000 and $70,000. These top-paying jobs are detailed below.

FAQ

What is the responsibility of a production planner?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. They ensure that the product or service is of high quality and meets client requirements.

What does it take for a logistics enterprise to succeed?

It takes a lot of skills and knowledge to run a successful logistics business. To communicate effectively with clients and suppliers, you must be able to communicate well. It is important to be able to analyse data and draw conclusions. You must be able to work well under pressure and handle stressful situations. To improve efficiency, you must be innovative and creative. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

It is important to be organized and efficient in order to meet tight deadlines.

What are the jobs in logistics?

There are different kinds of jobs available in logistics. Here are some:

-

Warehouse workers – They load, unload and transport pallets and trucks.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers – They sort and package freight at warehouses.

-

Inventory managers - They oversee the inventory of goods in warehouses.

-

Sales reps - They sell products and services to customers.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service representatives - They answer calls and emails from customers.

-

Shipping clerks - They process shipping orders and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors: They inspect outgoing and incoming products for any defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

Statistics

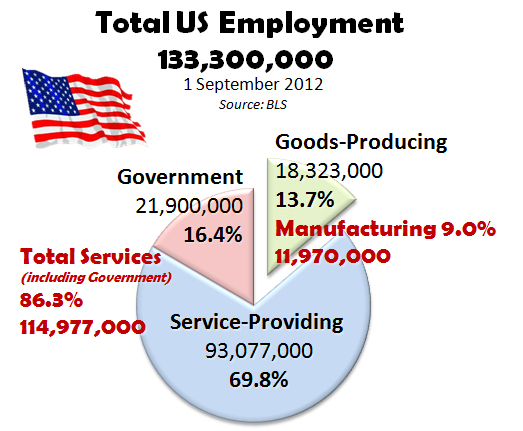

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing is widely used in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many companies have adopted lean manufacturing methods to increase their marketability. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

You can apply Lean Manufacturing to virtually any aspect of your organization. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three types of lean manufacturing.

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. It is better to repair a part than have it removed from the production line if it needs to be fixed. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous improvement involves continuous improvement of processes and people as well as tools.