Time manufacturing is a production method that involves having a continuous flow of products through the supply chain. It's an efficient and effective method of producing goods and avoiding excess production.

Just in time Production

Toyota Production System, or TPS, is a manufacturing system that employs just-in time production. It allows companies to deliver parts and raw materials directly to the manufacturing plant, so that they are available for use when needed by the production line.

This allows businesses to reduce inventory costs as well as storage space. This can allow a company to create less product and have more cash to spend in other areas.

Just-in time production can be seen in the automotive industry. The automobile industry is a good example of just-in-time production. Instead, they wait for orders from customers and keep as little inventory as possible.

They can use the PPS to check which parts were already ordered and which are still on hand. They can then plan the production of those parts accordingly.

The raw materials they order from suppliers can be used to lower the production cost and improve the quality of the components.

They can use a purchase order to specify when the parts should arrive at their facility. Then, they take the parts and start building the car.

The company will then deliver the finished car in a timely and efficient manner. It allows them to offer a product that is consistent and reliable.

Small companies often use just-in-time production when they need to produce a product, but don't have large inventories or a complicated supply chain. It can help them develop strong relationships with vendors and suppliers that will minimize the risk of stockouts or shortages.

The Just-in Time Method is especially helpful for manufacturing companies located near large cities, or with suppliers who can provide their components quickly and easily. It can improve employee retention if employees stay at the same firm for a longer period.

Just-in-time delivery is a method of supply chain management based on the idea that a product should arrive at an address and be ready to be shipped as soon as it is required by the client. It is essential for any company that sells products online and has customers who are in a hurry to receive their orders.

Just in time shipping is so popular, mainly because it allows for retailers to provide customers with more convenient options. Customers are able to select the most convenient and fast shipping method for their order.

Just-in time delivery can be a good way for businesses react to supply chains that fail due to unforeseeable delays or accidents. This allows companies to remain in the business and stay competitive.

FAQ

What skills should a production planner have?

To become a successful production planner, you need to be organized, flexible, and able to multitask. It is also important to be able communicate with colleagues and clients.

What does it take to run a logistics business?

You need to have a lot of knowledge and skills to manage a successful logistic business. Good communication skills are essential to effectively communicate with your suppliers and clients. You will need to know how to interpret data and draw conclusions. You must be able manage stress and pressure under pressure. To improve efficiency, you must be innovative and creative. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

To meet tight deadlines, you must also be efficient and organized.

What makes a production planner different from a project manger?

The difference between a product planner and project manager is that a planer is typically the one who organizes and plans the entire project. A production planner, however, is mostly involved in the planning stages.

What is the role of a manager in manufacturing?

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They must also be alert to any potential problems and take appropriate action.

They must also be able to communicate with sales and marketing departments.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

Why is logistics important in manufacturing?

Logistics are essential to any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

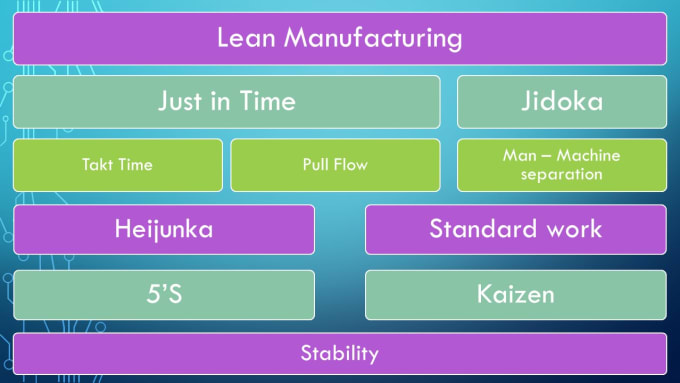

How to Use Lean Manufacturing for the Production of Goods

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination of defects and waste throughout the value stream. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing practices are widespread in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Five fundamental principles underlie lean manufacturing.

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many businesses have adopted lean production techniques to make them more competitive. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

It can be applied to any aspect of an organisation. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types in lean manufacturing

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.