The National Network for Manufacturing Innovation is primarily focused on developing cutting-edge manufacturing technologies. This interagency initiative was announced by President Obama in his FY 2013 budget proposal. This interagency initiative is designed to bring together federal agencies, community colleges, university engineering schools and other institutions in order to commercialize new manufacturing technologies.

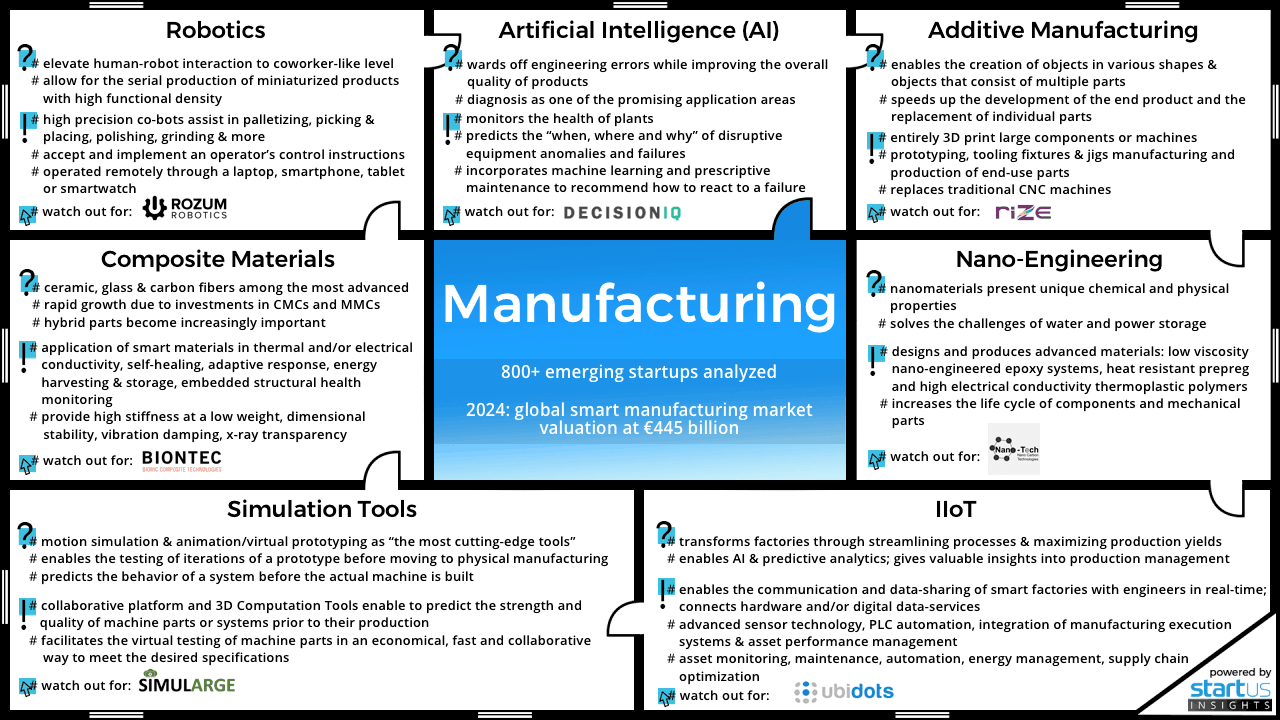

Manufacturing plays an important role in the American economy. This sector is a source of good jobs for American workers. Manufacturing companies invest in technological innovations to ensure they remain competitive. These innovations include automation and green energy sources. Companies invest in machine-downtime solutions. Innovative products such as autonomous mobile robots can reduce labor costs while increasing productivity. Additionally, companies invest in technologies that reduce the waste of resources, such as smart sensor technology.

The "Maker's Economy" will revolutionize how products are made. This is an economy where manufacturing users are actively involved in designing and building new products. The manufacturing sector is expected to take advantage of these innovations to boost productivity, improve operational efficiency, and enhance decision-making. It is expected to contribute significantly to the country's overall productivity. The United States has been a leader in manufacturing for many years.

The "Maker's Economy" is built on a range of technologies including smart factories, artificial intelligence, and other intelligent systems. These innovations improve manufacturing productivity by increasing worker efficiency and decreasing the amount of time it takes to produce a product. The Industrial Internet of Things (IIoT) uses sensors and data to help guide tasks. It also allows continuous monitoring of industrial assets. Secure connectivity is crucial for IIoT. It is expected that it will improve warehousing efficiency as well as supply chain visibility.

The National Network for Manufacturing Innovation will be made up of at least fifteen manufacturing institutes, and it is expected to help accelerate the development of manufacturing technologies. This network will also include public/private partnerships between government agencies and private companies.

There are currently 14 institutes for manufacturing innovation in the United States. In May 2013, the Commerce Department will fund three more. The National Institute of Standards and Technology will fund two Institutes. This will provide a total of up to $70 million per institute over five to seven years.

Each Institute for Manufacturing Innovation is going to have its own unique research focus. They will function as manufacturing innovation hubs in state and local economic areas. These Institutes will also help manufacturers integrate their capabilities. These institutes will provide manufacturers access to cutting edge equipment and technologies, as well as provide opportunities for workforce training. They will also help manufacturers solve cross-cutting challenges in advanced manufacturing.

The Network for Manufacturing Innovation is a broad-based program that aims at accelerating the commercialization, application and transfer of innovative manufacturing technologies. It also seeks to strengthen the state's and local economies. The U.S. Department of Energy's National Institute of Standards and Technology will oversee the operation of the institutes.

FAQ

What is the responsibility of a production planner?

Production planners ensure all aspects of the project are delivered within time and budget. They make sure that the product and services meet client expectations.

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP), or production planning, is the process by which you determine what products are needed at any given time. This is accomplished by forecasting the demand and identifying production resources.

Scheduling refers to the process of allocating specific dates to tasks in order that they can be completed within a specified timeframe.

What does warehouse mean?

Warehouses and storage facilities are where goods are kept before being sold. It can be indoors or out. Sometimes, it can be both an indoor and outdoor space.

Why automate your warehouse?

Modern warehousing is becoming more automated. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses need to adapt quickly to meet changing needs. Technology investment is necessary to enable warehouses to respond quickly to changing demands. The benefits of automating warehouses are numerous. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety is boosted

-

Eliminates bottlenecks

-

Allows companies scale more easily

-

Increases efficiency of workers

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

This ensures that quality products are delivered promptly

-

Eliminates human error

-

Helps ensure compliance with regulations

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use Lean Manufacturing for the Production of Goods

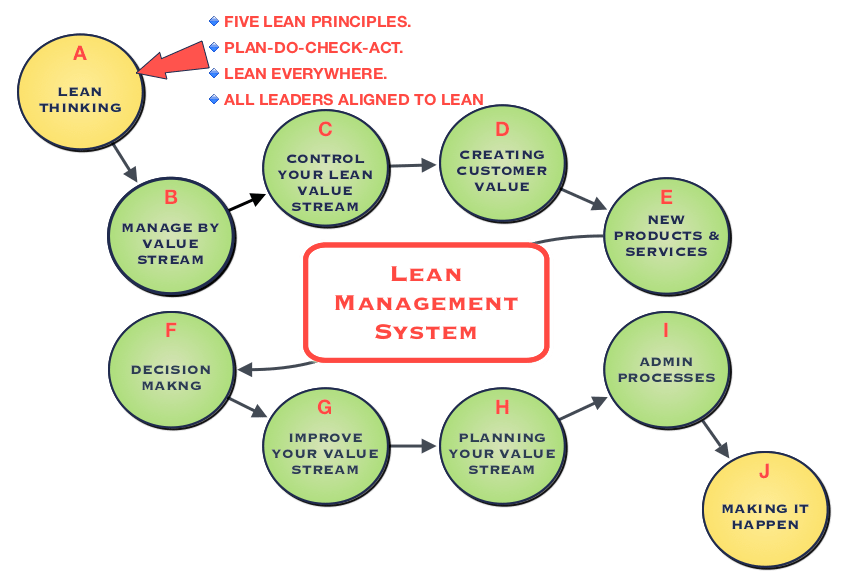

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination of defects and waste throughout the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing is about eliminating activities that do not add value, such as inspection, rework, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Lean manufacturing is based on five principles:

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many companies have adopted lean manufacturing methods to increase their marketability. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

It can be applied to any aspect of an organisation. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three main types in lean manufacturing

-

Just-in Time Manufacturing, (JIT): This kind of lean manufacturing is also commonly known as "pull-systems." JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. You should repair any part that needs to be repaired during an assembly line. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.