Manufacturing Phoenix, an Arizona company, provides a variety of products to the federal governments. It also provides products similar to the federal government for individuals and commercial customers. All production can be done in one location, with all resources located within a few feet of each others. The company also offers employment opportunities to people with disabilities for over 40 years. Its manufacturing division employs 70 people.

Honeywell Aerospace

Honeywell Aerospace, an aerospace firm that creates new transportation solutions, is located in the Phoenix area. The company's products improve flight safety and fuel efficiency as well as improving runway traffic. Its products can be found in nearly all commercial airliner. Honeywell Aerospace was also instrumental in the development and production of 2001: A Space Odyssey. Honeywell Aerospace also manufactures systems for the International Space Station.

In 2016, Honeywell opened a Phoenix reactive metal alloy manufacturing plant. The facility converted an outdated flame spray facility in order to produce parts made of titanium or aluminium alloys. By 2017, Honeywell plans to begin producing parts made of Inconel 718 in this facility. The facility has attracted more than $25million in investment from Honeywell.

Raytheon Technologies Corp.

Raytheon Technologies Corp. a multinational aerospace-defense conglomerate with headquarters located in Arlington Virginia. It is the largest manufacturer of military equipment worldwide. Its products include weapons, missiles, and aircraft. Raytheon is an aerospace and defense company that is also a market leader.

Raytheon has a long history in the defense and aerospace sectors. The company's aerial navigation systems division, for example, accounts for 27.4% of the company's net sales. It also manufactures electrical and mechanical equipment for planes.

Benchmark Electronics

Benchmark Electronics, a contract electronics manufacturer company, is located in Tempe Arizona. The Phoenix-based ODM has over 13,000 worldwide employees. The company operates offices in Tempe Marketplace, Scottsdale, as well as Tempe Marketplace. Gayla Delly was recently promoted to CEO.

Vertically integrated engineering and manufacturing services are offered by the Phoenix manufacturing facility. Its capabilities include embedded electronics design and microwave and RF component manufacturing. Additionally, the company provides aftermarket services. It serves many customers in the aerospace, defense, and industrial markets.

FAQ

What are the 7 R's of logistics?

The 7R's of Logistics is an acronym for the seven basic principles of logistics management. It was published in 2004 by the International Association of Business Logisticians as part of their "Seven Principles of Logistics Management" series.

The following letters form the acronym:

-

Responsive - ensure all actions are legal and not harmful to others.

-

Reliable - You can have confidence that you will fulfill your promises.

-

Use resources effectively and sparingly.

-

Realistic - Take into consideration all aspects of operations including cost-effectiveness, environmental impact, and other factors.

-

Respectful - show respect and treat others fairly and fairly

-

You are resourceful and look for ways to save money while increasing productivity.

-

Recognizable provides value-added products and services to customers

What are manufacturing and logistics?

Manufacturing is the production of goods using raw materials. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. Manufacturing and logistics are often considered together as a broader term that encompasses both the process of creating products and delivering them to customers.

How can manufacturing efficiency be improved?

First, we need to identify which factors are most critical in affecting production times. We must then find ways that we can improve these factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you identify them, look for solutions.

What does manufacturing mean?

Manufacturing Industries are companies that manufacture products. These products are sold to consumers. These companies employ many processes to achieve this purpose, such as production and distribution, retailing, management and so on. They create goods from raw materials, using machines and various other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

What is the responsibility of a production planner?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. They make sure that the product and services meet client expectations.

How does a production planner differ from a project manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

Six Sigma and Manufacturing

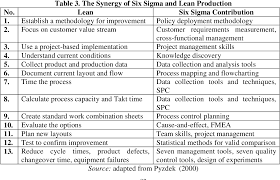

Six Sigma is defined as "the application of statistical process control (SPC) techniques to achieve continuous improvement." Motorola's Quality Improvement Department created Six Sigma at their Tokyo plant, Japan in 1986. The basic idea behind Six Sigma is to improve quality by improving processes through standardization and eliminating defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma seeks to reduce variation between the mean production value. You can calculate the percentage of deviation from the norm by taking a sample of your product and comparing it to the average. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. You'll also want to determine whether these variations are random or systematic. Random variations happen when people make errors; systematic variations are caused externally. You could consider random variations if some widgets fall off the assembly lines. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

Once you identify the problem areas, it is time to create solutions. It might mean changing the way you do business or redesigning it entirely. You should then test the changes again after they have been implemented. If they fail, you can go back to the drawing board to come up with a different plan.