There are many manufacturing options depending on the type and purpose of the product. Manufacturing can be done either by machine or hand. A manufacturing business may sell its goods to retailers, wholesalers, or consumers directly. The business may also sell its products through an online retailer.

The materials and equipment required to manufacture a product are the first step in manufacturing. Manufacturing businesses can choose to either purchase raw materials from suppliers or make their own. A jewelry maker could purchase components for a new piece of jewelry, and then combine them with a few other tools to build the finished product.

Some manufacturing processes require sophisticated machinery and tools. Cell phones, for instance, are made from raw materials and must be combined by sophisticated tools. The products are then shipped directly to the customer.

Manufacturing businesses may need to pay more for skilled workers in order to make a better product. Manufacturing is an expensive and time-consuming business that can take years of growth. For a business to be able to last the long-term, it may need to have a large cash reserve. Also, a manufacturing company may have to hire staff as needed.

Manufacturing is an attractive career choice. Manufacturing businesses may discover that the best products to market are those that customers already own. A manufacturing business may find it necessary to produce more products while reducing waste. Manufacturing isn’t for everyone.

Manufacturing can be challenging, especially if it isn't done well. Manufacturing businesses might find it difficult to find workers to work at all hours of day or to finish their work on time. This could lead to higher costs and lower profits. Manufacturing requires large investments in equipment and labor.

Manufacturing has a long history. That is what is most important. Manufacturing began thousands of years ago, as an art form that was associated with traditional artifacts. Today, manufacturing is one of the most important economic activities in the world. The manufacturing industry helps industrializing nations to expand their economies through the provision of goods and employment opportunities.

The manufacturing process is complex. The process may include hundreds of steps. The manufacturing process is also subject to quality control. Quality control is important because it helps to ensure that the finished product is safe for use, and that the brand identity of the product is protected. This is especially true if the manufacturer intends on selling its finished goods to wholesalers and consumers.

The manufacturing process may take place in virtually any location. Although there are many types of manufacturing, they all fall within one of three categories: discrete, process, or make-to-order. Each has its benefits and disadvantages. It is essential to understand each type of manufacturing process in order to benefit your company.

FAQ

Why automate your factory?

Automation has become increasingly important in modern warehousing. E-commerce has increased the demand for quicker delivery times and more efficient processes.

Warehouses must be able to quickly adapt to changing demands. Technology investment is necessary to enable warehouses to respond quickly to changing demands. Automating warehouses has many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Increases accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Allows companies scale more easily

-

Increases efficiency of workers

-

This gives you visibility into what happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

Ensures quality products are delivered on time

-

Eliminates human error

-

This helps to ensure compliance with regulations

Why is logistics important in manufacturing

Logistics is an integral part of every business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics plays a significant role in reducing cost and increasing efficiency.

What is the importance of automation in manufacturing?

Automating is not just important for manufacturers, but also for service providers. It allows them to offer services faster and more efficiently. It helps them to lower costs by reducing human errors, and improving productivity.

What are the 7 Rs of logistics management?

The 7R's of Logistics is an acronym for the seven basic principles of logistics management. It was published in 2004 by the International Association of Business Logisticians as part of their "Seven Principles of Logistics Management" series.

The acronym consists of the following letters:

-

Responsible – ensure that all actions are legal and don't cause harm to anyone else.

-

Reliable – have faith in your ability and capability to keep promises.

-

Use resources effectively and sparingly.

-

Realistic – Consider all aspects, including cost-effectiveness as well as environmental impact.

-

Respectful - show respect and treat others fairly and fairly

-

Resourceful - look for opportunities to save money and increase productivity.

-

Recognizable - Provide value-added services to customers

What is the difference in Production Planning and Scheduling, you ask?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. This is done through forecasting demand and identifying production capacities.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

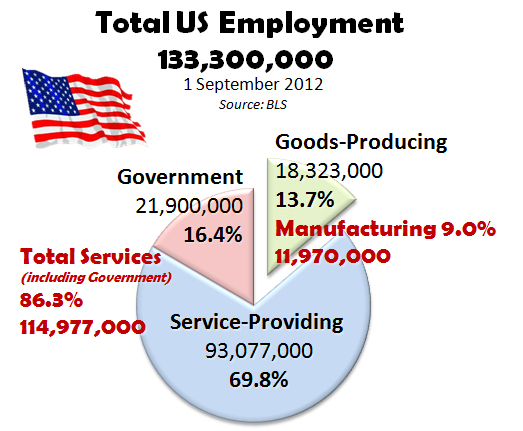

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

Six Sigma in Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department, Tokyo, Japan, developed it in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma aims to reduce variation in the production's mean value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If this deviation is too big, you know something needs fixing.

The first step toward implementing Six Sigma is understanding how variability works in your business. Once you have a good understanding of the basics, you can identify potential sources of variation. You'll also want to determine whether these variations are random or systematic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. You could consider random variations if some widgets fall off the assembly lines. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you have identified the problem, you can design solutions. The solution could involve changing how you do things, or redesigning your entire process. You should then test the changes again after they have been implemented. If they don't work, you will need to go back to the drawing boards and create a new plan.