Part-time or full-time jobs in logistics are available for both federal and local governments. They offer a number of advantages for job seekers. These include stable income, good benefits, and good income. The government can be a great place to get experience in this industry.

The Logistics Management Specialist is responsible, for example for the coordination of the supply chain. They coordinate deliveries, manage supplier contracts, and conduct audits. They also work to identify deficiencies in supply chains and develop contingency plans. You will need to have strong communication skills, good typing skills, and knowledge about government procurement regulations.

Supply Chain Management Officers may work for either the Department of Veterans Affairs, or the Department of Homeland Security. The first requires an in-depth knowledge of the federal government's procurement regulations. While the second position involves managing logistics operations, sourcing supplies and managing supply chain management. Depending on the job, candidates are required to have a bachelor's degree or higher. In addition, applicants are expected to have a solid knowledge of the business culture and regulations of the state they're applying for. Certain positions may require security clearances. In these cases, a background check may be necessary.

Another job for government logistics specialists is to quickly deploy materials after an emergency. The North Carolina Department of Public Safety, for example, offers a role in distribution of disaster logistics. Candidates must have at minimum four years relevant experience. Candidates must be able to manage a team of people and work in stressful situations.

Also, departmental levels require Logistics Management Specialists. The role of a logistics specialist closely mirrors that of Federal Aviation Administration. The qualifications include an advanced degree, specialized knowledge in operations or project managing, and a background of logistics management.

If you're interested in a career as a government logistics coordinator, you'll need to know how to manage a large volume of international travel. A background in procurement negotiations and supplier bid writing is also required. Ideally, candidates will have at least two years of relevant experience.

The federal government has many other supply-chain management roles you can apply to. Those positions are in the areas of air transport, road transport, warehousing, and distribution. The federal government offers nearly 25% of these jobs, while the states offer an additional 8%.

Visit USAJOBS, the website of the federal government to find many job opportunities. You can also search based on title and degree type. A majority of these positions require at most a bachelor's level of education, but some may require a Master's. Smaller organizations also have supply chain specialists jobs. A majority of supply chain professionals must have at least one (1) year of specialized experience in order to apply for a job.

There are many positions available for data scientists. Data Scientists support government programs and assist in the creation of strategic plans.

FAQ

Why automate your warehouse?

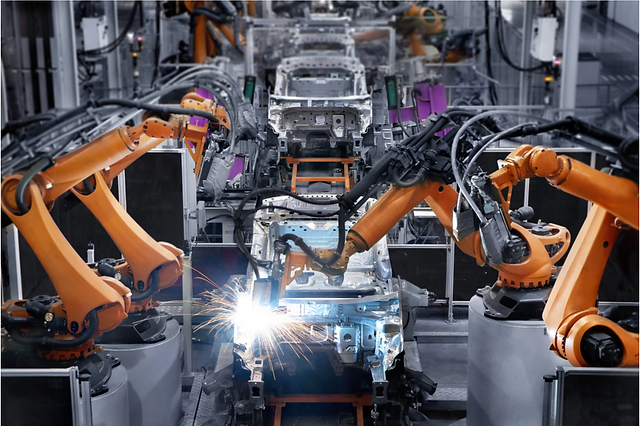

Automation has become increasingly important in modern warehousing. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses must adapt quickly to meet changing customer needs. Technology is essential for warehouses to be able to adapt quickly to changing needs. Automation warehouses can bring many benefits. These are some of the benefits that automation can bring to warehouses:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Boosts safety

-

Eliminates bottlenecks

-

Companies can scale more easily

-

Workers are more productive

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Reducing downtime and increasing uptime

-

This ensures that quality products are delivered promptly

-

Eliminates human error

-

It ensures compliance with regulations

How does manufacturing avoid bottlenecks in production?

You can avoid bottlenecks in production by making sure that everything runs smoothly throughout the production cycle, from the moment you receive an order to the moment the product is shipped.

This includes planning for capacity requirements as well as quality control measures.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma is a management method that helps to improve quality and reduce waste.

It's all about eliminating variation and creating consistency in work.

What are the responsibilities of a manufacturing manager

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They should also be aware and responsive to any company problems.

They should also know how to communicate with other departments such as sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

How can I learn about manufacturing?

The best way to learn about manufacturing is through hands-on experience. If that is not possible, you could always read books or view educational videos.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to Use Six Sigma in Manufacturing

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you understand this, you can then identify the causes of variation. It is important to identify whether the variations are random or systemic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. You could consider random variations if some widgets fall off the assembly lines. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. The solution could involve changing how you do things, or redesigning your entire process. Test them again once you've implemented the changes. If they fail, you can go back to the drawing board to come up with a different plan.