The foundation of continuous improvement is PDCA, which stands for Plan, Do, Check, Act. If it's done correctly, this method of improving can be highly effective and produce substantial results. Employee involvement is key to continuous improvement, and a variety of resources are required to execute the process. However, measurement and costing are just two benefits of the process. The PDCA cycle is not complete without the involvement of employees and customers.

PDCA cycle

Continuous improvement requires that you apply the PDCA cycle to every aspect of your business. This cycle works by repeatedly improving a process, building on previous improvements. The team may find new patterns in data, or they may discover a baseline. Both of these can reveal areas that need improvement. The PDCA Cycle is a great tool for identifying improvements opportunities. However, you must use it carefully and in a controlled way.

Employee involvement

There are many ways to describe employee involvement, but all successful organizations recognize its importance. Research has shown that employee involvement is closely linked to key work outcomes. There are four types of employee involvement. They can be classified as: representative participation through unions; direct communication; upward problem solving; and teamwork. These forms of employee involvement are often reinforced through the culture, environment, and leadership of an organization. These are some examples for employee involvement.

Measuring

Many companies now include measurements in their continuous improvements initiatives. W. Edwards Deming introduced the Deming cycle. It includes a Check phase, which evaluates progress against goals. If the results fall below expectations, adjustments are made to improve them. Unless satisfactory results are obtained, the cycle continues. Continuous improvement processes are an integral part of the process.

Costs

For CI to be considered cost-effective, it is essential that an enterprise-wide cost evaluation of CI efforts be done. The cost-benefit analysis should take into account the business imperative for achieving high customer satisfaction scores and employee engagement scores. In order to be successful, the cost-benefit assessment should also include the ROI for CI initiatives and fine-tuning the budgets. The cost-benefit assessment should include benchmarking key business processes against industry averages, as well as key performance areas.

Benefits

The benefits of continuous improvement are clear. A process that focuses on learning and failure is more likely to lead to major breakthroughs. Employees will feel more invested in the company if they are encouraged to look for ways to improve. Also, employees who are more involved in testing new technologies and tools might be empowered. And the benefits of continuous improvement go beyond saving money. Employee satisfaction is improved and work can be made easier by making positive changes.

FAQ

What is the job of a production plan?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. They also ensure the quality of the product and service meets the client's requirements.

How can excess manufacturing production be reduced?

The key to reducing overproduction lies in developing better ways to manage inventory. This would decrease the time that is spent on inefficient activities like purchasing, storing, or maintaining excess stock. We could use these resources to do other productive tasks.

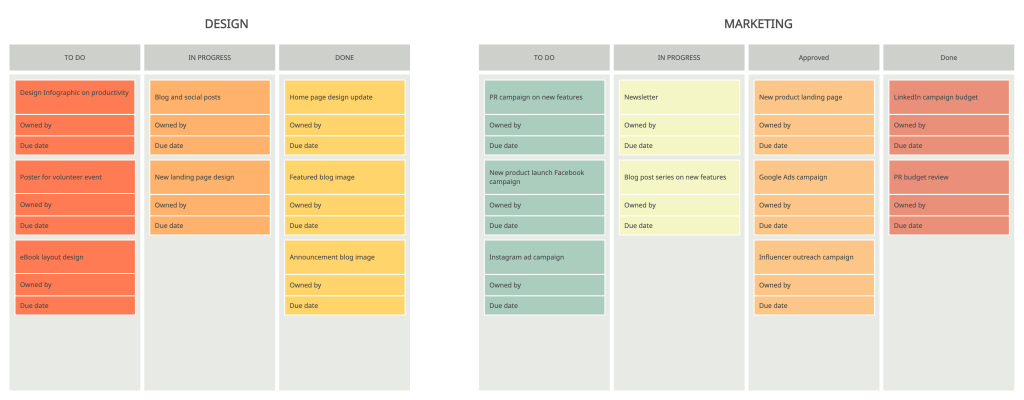

A Kanban system is one way to achieve this. A Kanban board, a visual display to show the progress of work, is called a Kanban board. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state is assigned a different priority.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This allows you to keep work moving along while making sure that no work gets neglected. Managers can view the Kanban board to see how much work they have done. This information allows managers to adjust their workflow based off real-time data.

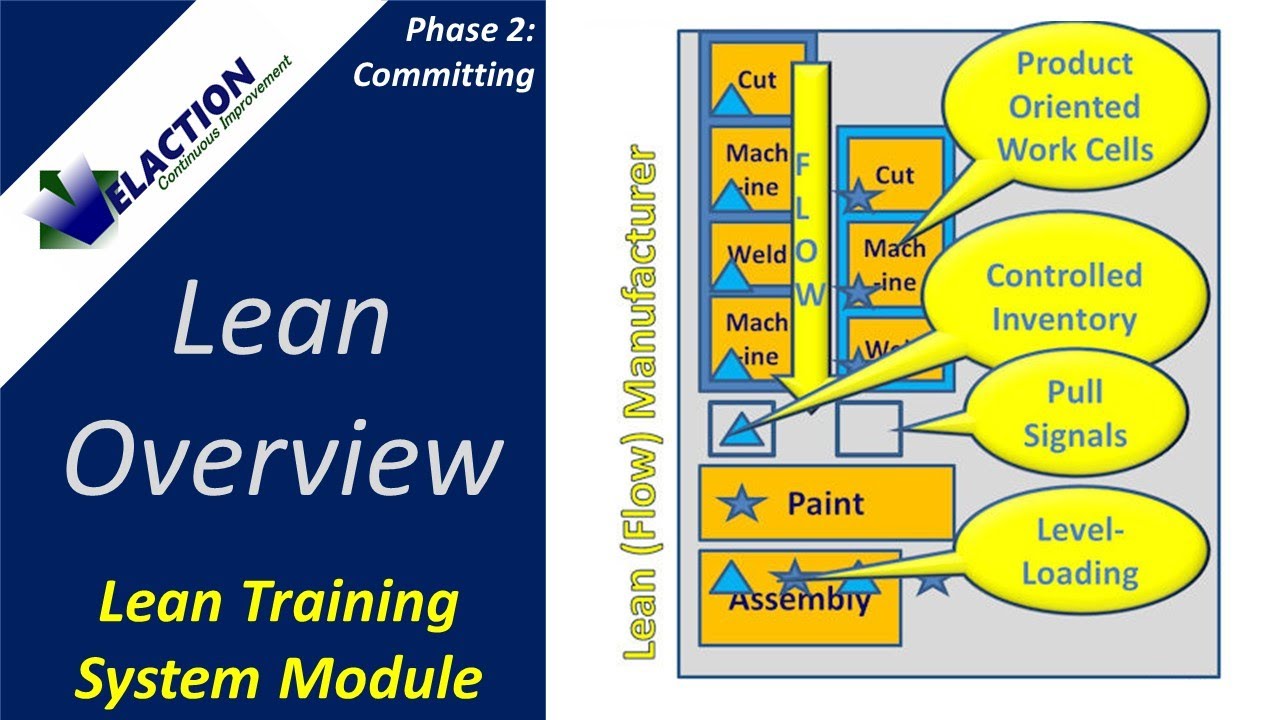

Lean manufacturing is another option to control inventory levels. Lean manufacturing is about eliminating waste from all stages of the production process. Any product that isn't adding value can be considered waste. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

Manufacturers can reduce their costs and improve their efficiency by using these ideas.

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. Forecasting demand is one way to do this.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

How can efficiency in manufacturing be improved?

First, we need to identify which factors are most critical in affecting production times. Next, we must find ways to improve those factors. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you have identified them, it is time to identify solutions.

Why automate your warehouse

Modern warehousing is becoming more automated. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses need to adapt quickly to meet changing needs. They must invest heavily in technology to do this. The benefits of automating warehouses are numerous. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety increases

-

Eliminates bottlenecks

-

Companies can scale up more easily

-

Workers are more productive

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Reduces downtime and improves uptime

-

You can be sure that high-quality products will arrive on time

-

Eliminates human error

-

It ensures compliance with regulations

What are manufacturing & logistics?

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

What are the 4 types of manufacturing?

Manufacturing is the process that transforms raw materials into useful products. It can involve many activities like designing, manufacturing, testing packaging, shipping, selling and servicing.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to use the Just-In Time Method in Production

Just-in-time is a way to cut costs and increase efficiency in business processes. It's a way to ensure that you get the right resources at just the right time. This means you only pay what you use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He noticed that workers were often paid overtime when they had to work late. He realized that workers should have enough time to complete their jobs before they begin work. This would help increase productivity.

JIT is a way to plan ahead and make sure you don't waste any money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This will prevent you from spending extra money on unnecessary things.

There are several types of JIT techniques:

-

Demand-driven: This is a type of JIT where you order the parts/materials needed for your project regularly. This will allow you to track how much material you have left over after using it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: This type allows you to stock the materials needed for your projects ahead of time. This allows you to predict how much you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT : This is probably the most popular type of JIT. This is where you assign resources based upon demand. You might assign more people to help with orders if there are many. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based: This approach is very similar to resource-based. However, you don't just care about the number of people you have; you also need to consider how much each person will cost.

-

Price-based: This is similar to cost-based but instead of looking at individual workers' salaries, you look at the total company price.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT is another variant of resource-based JIT. Instead of looking at the labor costs and time it takes to make a product, think about its quality.

-

Value-based JIT: One of the most recent forms of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based is an inventory-based system that measures the number of items produced at any given moment. It's used when you want to maximize production while minimizing inventory.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It's the process of scheduling delivery of components immediately after they are ordered. It is essential because it reduces lead-times and increases throughput.