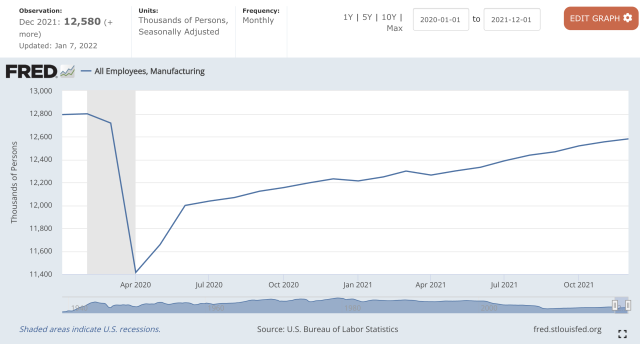

The United States has a rising manufacturing sector. The United States is the third largest manufacturer in the world. The total manufacturing output hit a record high in Q1 2018, exceeding $1.95 trillion, and is on course to exceed that high by 2022. Many factors are responsible for this, including automation and productivity growth.

Institutes that offer High Wage America

High-wage work is a key component of the High Wage America Movement. Low wages and high levels in inequality continue to be a problem for the American economy, as the country continues its slow recovery after the Great Recession. But there are solutions to this current low-wage crisis. By developing an agenda for high-wage jobs, states and local stakeholders can work to improve the current conditions of the American workforce.

The first step in implementing a sustainable manufacturing plan is to get it implemented. This involves a strategy to address issues such as wage stagnation, poor work conditions, and insufficient training. This can only be achieved if the United States fights unfair trade practices. It must also implement policies that help manufacturing communities prosper.

Automated manufacturing technologies

There's no doubt that automation technologies are changing the way we make products. Companies and workers have seen a dramatic reduction in costs and higher profits thanks to automated manufacturing technologies. In the US, government policy is making a difference as well, by encouraging the development of new technologies. Actually, government policies can be a boon for businesses by encouraging the creation of new technologies.

Automation in manufacturing began in the US in the early 1900s with the introduction of the Ford Motor Company's first production line. This line was the most advanced in the world and dramatically improved Ford's production. It cut down the time taken to assemble a car from 12 to just over one hour.

Productivity growth

There are many factors that point to manufacturing productivity growth. Large gaps in productivity between the best-run companies and others across many industries indicate that productivity growth may be possible. Access to technology and mobility to move production is critical, as well as increased infrastructure investment. Productivity is generally measured by the output divided by the inputs, which most often include labor hours. Outputs are measured in either units produced or sales.

The most common measure of productivity is labor productivity. This measure is a ratio of output to hours worked. It can also be broken down by wage levels or technological advances. Productivity growth in the workplace directly impacts corporate profits. Employers who work more efficiently produce more output for every hour of their labor.

Outsourcing can have a major impact

Multifaceted impacts of outsourcing on US manufacturing are possible. Sometimes outsourcing is a good thing. It allows the country compete with countries with lower labor cost. Outsourcing can have the opposite effect and lead to the loss of American jobs. Sometimes, outsourcing can result in American jobs being replaced with foreign workers. Other times, it can lead American workers to earn lower wages.

Outsourcing started in America and has since expanded to other countries. To cut costs, some companies have spun off their "core" operations. Sodexo which provides food services, IBM, and UPS were just a few examples. Companies like Foxconn, which manufactures computers, also started outsourcing. Apple and Foxconn are two examples of companies that have outsourced all their manufacturing.

FAQ

What are the responsibilities of a manufacturing manager

The manufacturing manager should ensure that every manufacturing process is efficient and effective. They should also be aware of any problems within the company and act accordingly.

They should also be able and comfortable communicating with other departments like sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

What is production management?

Production Planning refers to the development of a plan for every aspect of production. This document will ensure everything is in order and ready to go when you need it. This document should include information about how to achieve the best results on-set. This includes shooting schedules, locations, cast lists, crew details, and equipment requirements.

The first step is to decide what you want. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you've identified the locations and scenes you want to use, you can begin to plan what elements you need for each scene. If you decide you need a car and don't know what model to choose, this could be an example. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

After you have chosen the right car, you will be able to begin thinking about accessories. Do you need people sitting in the front seats? Perhaps you have someone who needs to be able to walk around the back of your car. Perhaps you would like to change the interior colour from black to white. These questions will help determine the look and feel you want for your car. Another thing you can do is think about what type of shots are desired. Are you going to be shooting close-ups? Or wide angles? Perhaps you want to show the engine or the steering wheel? These things will help you to identify the car that you are looking for.

Once you have determined all of the above, you can move on to creating a schedule. You can create a schedule that will outline when you must start and finish your shoots. The schedule will show you when to get there, what time to leave, and when to return home. So everyone is clear about what they need to do. Book extra staff ahead of time if you need them. You don't want to hire someone who won't show up because he didn't know.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects are quick and easy, while others take weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Multiple takes of the same location will lead to higher costs and take more time. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Budget setting is another important aspect in production planning. A realistic budget will help you work within your means. It is possible to reduce the budget at any time if you experience unexpected problems. But, don't underestimate how much money you'll spend. Underestimating the cost will result in less money after you have paid for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

How can we improve manufacturing efficiency?

First, we need to identify which factors are most critical in affecting production times. Then we need to find ways to improve these factors. You can start by identifying the most important factors that impact production time. Once you have identified the factors, then try to find solutions.

What can I do to learn more about manufacturing?

The best way to learn about manufacturing is through hands-on experience. But if that is not possible you can always read books and watch educational videos.

How can we reduce manufacturing overproduction?

It is essential to find better ways to manage inventory to reduce overproduction. This would reduce the time needed to manage inventory. We could use these resources to do other productive tasks.

You can do this by adopting a Kanban method. A Kanban board, a visual display to show the progress of work, is called a Kanban board. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state is assigned a different priority.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This allows you to keep work moving along while making sure that no work gets neglected. Managers can see how much work has been done and the status of each task at any time with a Kanban Board. This information allows them to adjust their workflow based on real-time data.

Lean manufacturing is another option to control inventory levels. Lean manufacturing seeks to eliminate waste from every step of the production cycle. Waste includes anything that does not add value to the product. Some common types of waste include:

-

Overproduction

-

Inventory

-

Packaging that is not necessary

-

Excess materials

These ideas can help manufacturers improve efficiency and reduce costs.

What are the logistics products?

Logistics are the activities involved in moving goods from point A to point B.

They encompass all aspects transport, including packaging and loading, transporting, storage, unloading.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They can also track shipments in transit and monitor quality standards.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing, often described as a set and practice of principles, is aimed at improving the quality, speed, cost, and efficiency of products, services, and other activities. It is about eliminating defects and waste from all stages of the value stream. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing can be found in many industries. Toyota's philosophy has been a key driver of success in many industries, including automobiles and electronics.

Five principles are the basis of lean manufacturing:

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow – Ensure that work flows smoothly throughout the process.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses are now using lean manufacturing to improve their competitiveness. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include higher customer satisfaction levels, reduced inventory levels as well as lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing (ZDM): ZDM focuses on ensuring that no defective units leave the manufacturing facility. It is better to repair a part than have it removed from the production line if it needs to be fixed. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. Continuous improvement refers to continuous improvement of processes as well people and tools.