Time manufacturing is a production method that involves having a continuous flow of products through the supply chain. It's an efficient and effective method of producing goods and avoiding excess production.

Just in Time Production

Toyota Production System (TPS) is used to manufacture Just-in-Time Production. The Toyota Production System (TPS) allows for companies to send parts and raw materials to the factory directly, so they can be used when the production line needs them.

Businesses can also reduce their inventory costs and save on storage space. This can allow a company to create less product and have more cash to spend in other areas.

A good example of just in time production is the automobile industry. Most car manufacturers are unable to afford to overproduce cars because they must sell them within one year. They wait for customer orders and try to keep as little stock as possible.

Using the PPS System, they are able to determine which parts have been already ordered and those that remain in stock. They can then plan the production of those parts accordingly.

The raw materials they order from suppliers can be used to lower the production cost and improve the quality of the components.

When they need to build a vehicle, they can create an order specifying when the parts will arrive at their location. Then, they take the parts and start building the car.

The company can then take the completed car to the customer for delivery in a timely manner. The company can provide a consistent and reliable product to its customers.

Just-in time production is often used by small companies who need to create products but do not have a large inventory or complex supply chains. It helps them build strong relationships with suppliers and vendors that reduce the risk of shortages and stockouts.

Using the just in time method is especially beneficial for manufacturing firms that are located near a major city or have suppliers that can provide their parts quickly and easily. The method also helps to retain employees by allowing them to stay with the company for long periods of time.

Just-in-time delivery is a method of supply chain management based on the idea that a product should arrive at an address and be ready to be shipped as soon as it is required by the client. This type of delivery is important for any business that has an ecommerce presence and customers who need their products delivered as soon as possible.

Just in Time Delivery is very popular among retailers because it allows them to offer more convenient and faster shipping methods. It lets customers choose the fastest, most convenient delivery option available to them for their purchase. This allows them to make an informed decision.

Just-in time delivery can be a good way for businesses react to supply chains that fail due to unforeseeable delays or accidents. This can allow businesses to stay in business and remain competitive.

FAQ

How can manufacturing avoid production bottlenecks

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes both planning for capacity and quality control.

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma management is a system that improves quality and reduces waste within your organization.

It focuses on eliminating variation and creating consistency in your work.

What is the importance of automation in manufacturing?

Automation is important not only for manufacturers but also for service providers. It allows them to offer services faster and more efficiently. In addition, it helps them reduce costs by reducing human errors and improving productivity.

Why is logistics important in manufacturing

Logistics are an essential component of any business. They are essential to any business's success.

Logistics play a key role in reducing expenses and increasing efficiency.

What is the difference between Production Planning and Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. This is done through forecasting demand and identifying production capacities.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

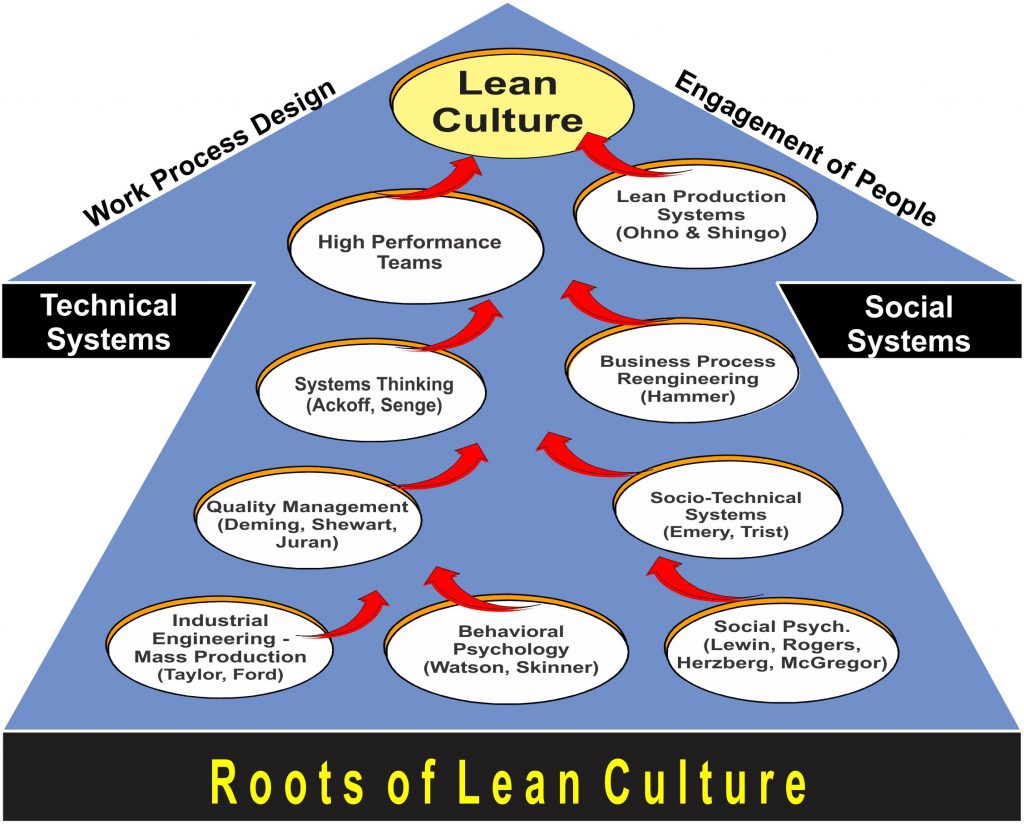

How to Use lean manufacturing in the Production of Goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean Manufacturing is one of the most efficient ways to manage the entire value chains, including suppliers and customers as well distributors and retailers. Many industries worldwide use lean manufacturing. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize and simplify - Make your processes as consistent as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Although lean manufacturing isn't a new concept in business, it has gained popularity due to renewed interest in the economy after the 2008 global financial crisis. Many businesses have adopted lean manufacturing techniques to help them become more competitive. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

Lean manufacturing has many benefits in the automotive sector. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

The principles of lean manufacturing can be applied in almost any area of an organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three types of lean manufacturing.

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous improvement refers to continuous improvement of processes as well people and tools.